Table of Content:

- What Exactly Is Mobile On-Site Crushing?

- The Immediate Advantages of Crushing On-Site

- How It Works: The On-Site Crushing Process

- A Sustainable Business Advantage

- Michigan’s Growing Demand for On-Site Crushing

- Overcoming Common Concerns

- The Future of Demolition Waste Management

- Partner with Kraken Crushed Concrete

In every city skyline project or suburban redevelopment, one challenge repeats itself: what to do with the mountains of debris left behind after demolition. Concrete, asphalt, and brick-once the backbone of old structures-quickly become an expensive problem to haul, store, and dispose of. For decades, this waste was loaded into trucks and sent miles away to landfills or recycling centers. Today, that model is changing rapidly.

Thanks to mobile on-site crushing, project managers and contractors are rethinking how they handle demolition waste. Instead of paying to remove materials, they’re processing and reusing them right where the work happens. The shift isn’t just convenient—it’s cutting costs, shrinking carbon footprints, and turning construction waste into valuable, reusable aggregate.

The Problem with Traditional Waste Removal

Demolition waste management has long been a hidden cost in construction. Moving tons of concrete and asphalt from a site to a disposal area requires multiple truckloads, fuel, and labor. Add tipping fees at landfills and strict disposal regulations, and it becomes clear why waste management often eats into profit margins. Beyond costs, the environmental burden is immense. Every mile driven by a dump truck contributes to emissions, road wear, and traffic congestion. Even when the debris reaches a recycling facility, additional energy is spent processing it. Developers and general contractors in Michigan are under pressure to meet both sustainability goals and financial targets. This is where mobile on-site crushing services in Michigan are making a real impact.

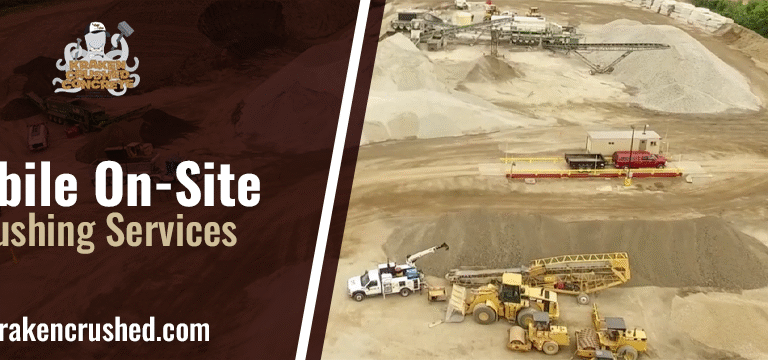

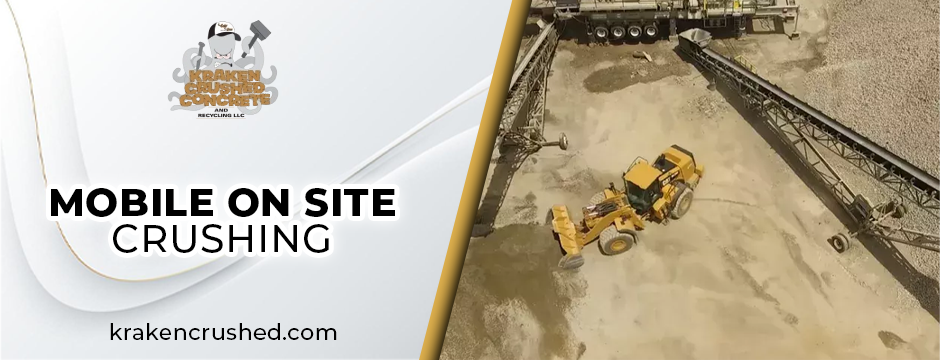

What Exactly Is Mobile On-Site Crushing?

Mobile on-site crushing is the process of bringing portable crushing equipment directly to a job site to recycle materials such as concrete, brick, stone, and asphalt into usable aggregates. Instead of moving waste to a distant facility, the crushing happens right where demolition occurs. At Kraken Crushed Concrete, for instance, heavy-duty mobile crushers and screeners are deployed to project sites across Michigan. The system is designed to break down large chunks of concrete or asphalt into uniform sizes suitable for road base, fill material, or new concrete production. The processed material can often be reused immediately on-site, saving both time and money.

The Immediate Advantages of Crushing On-Site

1. Dramatic Cost Savings

Transportation and landfill fees are two of the biggest expenses in demolition waste management. By eliminating the need to haul material off-site, contractors can save thousands per project. The savings multiply when the crushed product is reused for backfill or sub-base, reducing the need to purchase new aggregate. A mid-sized commercial demolition in Detroit, for example, generated nearly 3,000 tons of concrete waste. Using traditional hauling methods, the contractor faced an estimated $80,000 in disposal and material replacement costs. With mobile on-site crushing, that same concrete was processed and reused for site stabilization, reducing total costs by nearly 45%.

2. Reduced Project Timelines

Hauling waste can delay construction schedules by days or even weeks. Crushing on-site allows teams to continue grading, backfilling, or paving almost immediately after demolition. The efficiency keeps projects on schedule and helps contractors meet tight deadlines without the logistical headaches of off-site disposal.

3. Environmental Sustainability

Every ton of recycled material used on-site means one less ton mined from a quarry and one less truck on the road. Mobile on-site crushing supports Michigan’s sustainability goals by reducing CO₂ emissions, conserving raw resources, and minimizing landfill use. The environmental impact is significant. According to Environmental News Watch, mobile recycling of concrete and asphalt can reduce greenhouse gas emissions by up to 60% compared to conventional methods. This shift plays an important role in the construction industry’s move toward greener building practices.

How It Works: The On-Site Crushing Process

- Material Assessment – Before starting, experts assess the material composition, contamination levels, and the desired end product.

- Equipment Setup – The mobile crusher and screening units are transported to the site and positioned strategically.

- Processing – Excavators feed the crusher with concrete, asphalt, or brick. The machine breaks down the material and screens it by size.

- Reuse or Removal – The crushed material is either stockpiled for immediate reuse or hauled short distances for nearby construction.

This streamlined workflow ensures minimal downtime, optimized recycling, and reduced labor costs.

A Sustainable Business Advantage

For contractors and developers, adopting mobile on-site crushing is more than an operational improvement—it’s a competitive edge. Many municipalities and clients now favor bids that emphasize sustainability and resource efficiency.

By offering on-site recycling, contractors position themselves as environmentally responsible partners who understand modern construction priorities. Projects gain LEED points, community goodwill, and often qualify for sustainability incentives.

Additionally, keeping materials on-site reduces liability. Fewer trucks on public roads mean fewer opportunities for accidents or delays caused by hauling operations.

Michigan’s Growing Demand for On-Site Crushing

The demand for mobile on-site crushing services in Michigan continues to rise as cities revitalize aging infrastructure and promote sustainable building. From Detroit’s redevelopment corridors to industrial zones in Flint, contractors are turning to mobile crushing as a smarter, cleaner alternative.

Kraken Crushed Concrete has seen firsthand how this approach changes the dynamics of project management. With modern equipment and an experienced team, the company brings efficiency and reliability to sites that would otherwise struggle with waste logistics. Each project handled through mobile on-site crushing helps move Michigan closer to a zero-waste construction future.

Overcoming Common Concerns

Some contractors hesitate to use mobile crushing, assuming it’s only viable for large projects. In reality, modern mobile crushers come in various sizes and capacities, allowing them to handle anything from small residential tear-downs to major commercial demolitions.

Dust and noise are also manageable with today’s technology. Kraken’s crushers use water suppression systems and enclosed screening units to ensure clean and quiet operation. Local permitting is simplified because the process reduces truck movement and landfill reliance.

The Future of Demolition Waste Management

The future of demolition waste management will be defined by mobility and on-site solutions. Electric and hybrid crushers are already emerging, reducing fuel consumption and emissions even further. Integrated sensors and remote monitoring systems now allow operators to optimize performance and predict maintenance needs before downtime occurs.

As Michigan’s infrastructure evolves, mobile on-site crushing will remain at the heart of efficient, responsible construction practices. The ability to reclaim waste as a usable asset sets the stage for a more circular and sustainable construction economy.

Partner with Kraken Crushed Concrete

At Kraken Crushed Concrete, we believe that demolition waste should never be seen as a burden. With our advanced mobile on-site crushing solutions, we help contractors transform piles of debris into valuable resources that support the next phase of construction.

Our experienced team provides reliable service, rapid mobilization, and compliance with all safety and environmental standards. Whether you’re managing a small site or a large redevelopment project, Kraken ensures that your demolition waste is handled efficiently, economically, and responsibly.

If you’re ready to cut costs, reduce waste, and take your project’s sustainability to the next level, reach out to Kraken Crushed Concrete today. Discover how our mobile on-site crushing services in Michigan can make your next project smarter from the ground up.