Construction projects generate a significant amount of waste. Materials such as concrete, asphalt, bricks, and other debris accumulate quickly. Proper handling of this waste is crucial for maintaining efficiency, controlling costs, and protecting the environment. This is where crushing sites play a vital role. By processing construction waste on-site or nearby, crushing sites provide practical solutions for contractors and builders.

Understanding Crushing Sites

Table of Content:

A crushing site is a location where construction debris is processed into reusable materials. Concrete and asphalt are broken down into smaller aggregates. These aggregates can be used in new construction projects. Crushing sites reduce the need to transport waste to distant landfills. They also promote recycling, which is becoming increasingly important in the construction industry.

The main goal of crushing sites is to convert construction debris into usable material. This reduces the amount of waste sent to landfills. It also lowers transportation costs and supports sustainable construction practices. Contractors can rely on crushing sites to handle a wide range of materials efficiently.

Types of Materials Processed

Crushing sites handle different materials. Concrete is one of the most common. Once crushed, concrete can be reused in road base, driveways, or even new concrete mixes. Asphalt is another key material. Crushed asphalt Michigan is widely used for paving and road repair. Other materials such as brick, stone, and construction debris can also be processed. These materials are sorted, crushed, and prepared for reuse.

Processing materials at crushing sites helps maintain quality. Aggregates produced are graded according to size and quality standards. This ensures that recycled materials meet project specifications. Contractors can use these materials confidently, knowing they meet industry requirements.

Benefits of Using Crushing Sites

Cost Savings

One of the main advantages of crushing sites is cost reduction. Transporting waste to distant landfills is expensive. Hauling fees and tipping charges can quickly add up. By using a nearby crushing site, contractors can save on transportation costs. The material processed at the site can often be reused. This reduces the need to purchase new aggregates.

Environmental Benefits

Crushing sites are environmentally friendly. Recycling construction debris reduces landfill use. It also cuts down on carbon emissions from transportation. By reusing materials such as concrete and asphalt, projects can reduce their environmental footprint. This is important as sustainability becomes a priority in construction.

Space Management

Construction sites often have limited space for waste storage. Piles of debris can slow down work and create safety hazards. Crushing sites help manage space efficiently. Waste materials can be processed quickly and either reused on-site or transported in a controlled manner. This keeps the construction site organized and safe.

Improved Project Efficiency

Crushing sites enhance project efficiency. Materials can be processed near the site, reducing delays caused by transporting debris to distant locations. This ensures that work continues without interruptions. Contractors can plan projects with greater confidence, knowing that waste management will not cause unexpected delays.

Versatility

Crushing sites handle a variety of materials. They can process concrete, asphalt, brick, stone, and mixed construction debris. This versatility allows contractors to manage different types of waste using a single service. It simplifies logistics and reduces the need for multiple waste disposal methods.

The Role of Crushed Asphalt Michigan

Asphalt is one of the most common materials in construction projects. Roads, driveways, and parking lots generate large amounts of asphalt waste. Crushing sites in Michigan specialize in processing this material. Crushed asphalt Michigan can be reused for new paving projects, road repairs, or temporary driveways.

Using recycled asphalt is cost-effective. It reduces the need to purchase new asphalt. It also lowers transportation costs because the material can be reused locally. Additionally, recycled asphalt supports sustainable construction practices by reducing landfill use and carbon emissions.

Regulations and Compliance

Construction waste management is regulated by local and state authorities. Proper disposal and recycling practices are often required. Crushing sites help contractors comply with these regulations. By processing materials according to industry standards, contractors avoid fines and legal issues. Compliance also supports environmental responsibility.

Crushing sites maintain records of material processed, recycled, and transported. This documentation is important for reporting and permits. It also provides contractors with a clear overview of their waste management practices. By following regulations, contractors can operate safely and responsibly.

Best Practices for Using Crushing Sites

Contractors can maximize the benefits of crushing sites by following best practices. First, materials should be sorted before processing. Separating concrete, asphalt, and other debris improves efficiency and quality. Next, plan the logistics. Ensure that the crushing site is accessible and capable of handling the volume of materials.

Regularly inspect the materials produced. Check that crushed aggregates meet size and quality standards. Use the processed materials appropriately, based on project requirements. Finally, maintain communication with the crushing site operator. Clear communication ensures that materials are processed according to your specifications.

Economic Impact

The use of crushing sites has a broader economic impact. By recycling construction materials, contractors reduce the demand for new aggregates. This helps conserve natural resources. Local crushing sites also support jobs and stimulate the local economy. Recycling operations require skilled operators, equipment maintenance, and transportation services.

Furthermore, projects that use recycled materials can reduce overall costs. These savings can be reinvested into other areas of construction, improving project profitability. Contractors who adopt recycling practices can gain a competitive advantage in bidding for projects.

Safety Advantages

Construction sites are prone to accidents, especially when handling debris. Large piles of waste can pose hazards to workers and equipment. Crushing sites improve safety by controlling and processing debris in a controlled environment. Material is reduced to manageable sizes, reducing the risk of accidents. Safety protocols at the site ensure that workers and equipment operate efficiently.

How Crushing Sites Support Sustainable Construction

Sustainability is a growing concern in the construction industry. Crushing sites play a key role in reducing environmental impact. By converting waste into reusable materials, these sites promote a circular economy. This approach minimizes the need for new resources and reduces landfill usage. Projects that use recycled aggregates demonstrate a commitment to sustainable construction.

Recycling materials also reduces greenhouse gas emissions. Transportation of waste to distant landfills is minimized. The reuse of materials such as crushed asphalt Michigan supports eco-friendly practices. Sustainability initiatives can improve a company’s reputation and appeal to environmentally conscious clients.

Kraken-Crushed-Concrete’s Approach

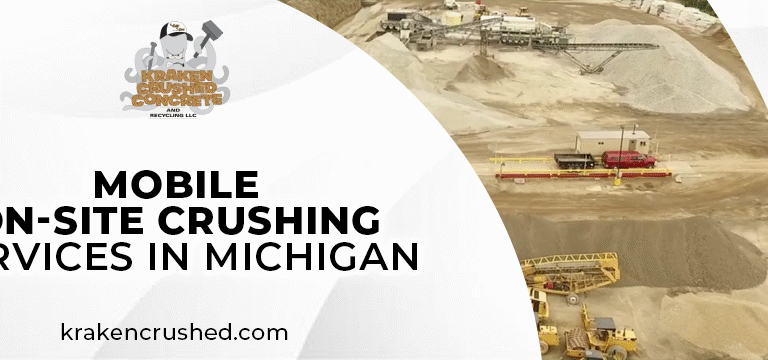

At Kraken-Crushed-Concrete, we provide comprehensive crushing and recycling services. Our mobile crushing units allow us to process materials directly at the job site. This reduces downtime, lowers costs, and supports sustainable practices. We specialize in concrete, asphalt, brick, and mixed construction debris.

Our team ensures that every batch of material meets quality standards. We provide crushed aggregates ready for reuse in your projects. By using our services, contractors can manage waste efficiently while keeping projects on schedule. We focus on reducing environmental impact and improving overall project efficiency in Michigan. Our commitment is to make construction waste management simple, effective, and eco-friendly for every client.

Conclusion

Crushing sites are essential for modern construction waste management. They provide cost savings, improve project efficiency, support sustainability, and ensure safety. Materials like concrete, asphalt, and mixed debris are processed into reusable aggregates. Crushed asphalt Michigan is a prime example of how recycling can reduce costs and environmental impact.

By using crushing sites, contractors can comply with regulations, maintain quality, and optimize resources. The role of these sites will continue to grow as the construction industry focuses on sustainable and efficient practices. They offer practical solutions for contractors, builders, and project managers looking to improve waste management.